Introduction

Electric motors are ubiquitous in our modern world, powering a wide range of machines and systems across various industries. From electric vehicles to industrial manufacturing equipment, electric motors play a critical role in driving innovation and improving sustainability. This article provides an extensive overview of electric motors, their various types, working principles, advancements in technology, and applications across different industries. It explores real-world case studies and highlights the efficiency and environmental benefits of electric motors. The article also discusses the challenges and future trends in electric motor technology, with expert insights and quotes. It concludes by emphasizing the implications of electric motors for industry and the environment and encourages further research and professional dialogue.

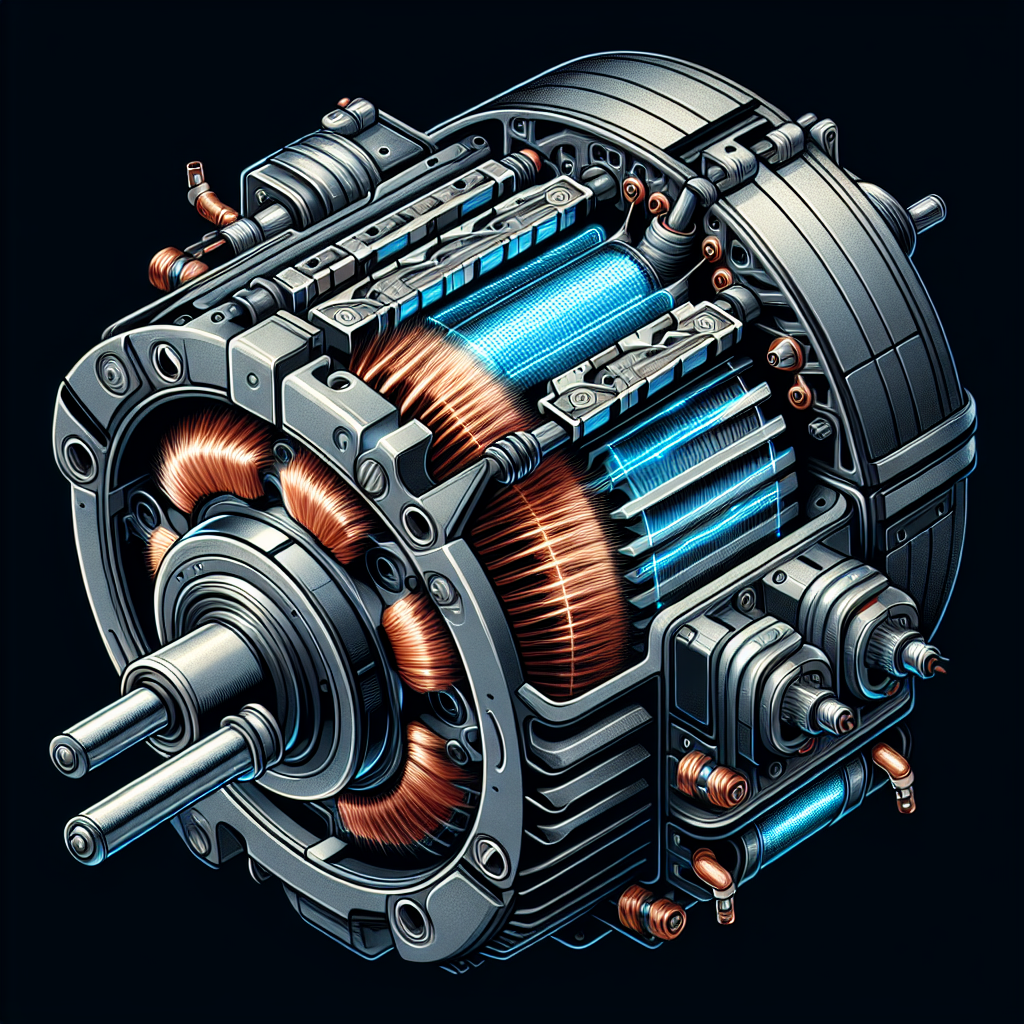

Overview of Electric Motors

Electric motors are devices that convert electrical energy into mechanical energy. They operate based on the principles of electromagnetism, where the interaction between electric currents and magnetic fields generates rotational motion. Electric motors consist of a rotor (rotating part) and a stator (stationary part). The rotor is typically made up of a coil of wire wound around a core that can rotate within a magnetic field generated by the stator. When an electric current flows through the coil, it creates a magnetic field that interacts with the stator's magnetic field, resulting in mechanical motion.

Importance of Electric Motors in Various Industries

Electric motors are essential in a wide range of industries, contributing to the efficient and sustainable operation of various systems. Dr. Paul Oh, Distinguished Professor of Robotics at Purdue University, highlights the significance of electric motors by stating, "Electric motors are the heart of many modern-day machines and systems, playing a critical role in driving innovation and improving sustainability." Some major industries where electric motors are widely used include:

Automotive Industry

The automotive industry has witnessed a significant shift towards electric vehicles (EVs) in recent years. Electric motors power the propulsion systems in EVs, offering several advantages over internal combustion engines, such as higher efficiency, lower emissions, and quieter operation. Chris Onder, Chief Engineer at General Motors, acknowledges the advancements in electric motor technology by stating, "Advancements in electric motor technology have allowed us to push the boundaries of efficiency and performance in our electric vehicles, providing an exciting driving experience while reducing emissions."

Industrial Manufacturing

Electric motors play a crucial role in industrial manufacturing processes, powering machinery and equipment such as pumps, compressors, conveyors, and robotics. They offer high efficiency, precise control, and reliability, contributing to increased productivity and reduced energy consumption.

Renewable Energy Systems

Renewable energy sources such as wind and solar power heavily rely on electric motors for converting kinetic or solar energy into electrical energy. Electric motors drive wind turbine generators, solar panel tracking systems, and hydroelectric power plants, enabling the generation of clean and sustainable energy.

Consumer Electronics

Electric motors are present in numerous consumer electronics products, including appliances, power tools, and entertainment systems. In these applications, electric motors provide the necessary mechanical motion for functions such as spinning, rotating, or linear movement.

Types of Electric Motors

Electric motors come in various types, each designed for specific applications and operating conditions. The most common types of electric motors include AC motors, DC motors, brushed motors, brushless motors, and stepper motors.

AC Motors

AC motors, or alternating current motors, are widely used in industrial and residential applications. They run on alternating current and include induction motors (both single-phase and three-phase) and synchronous motors. AC motors offer high reliability, low maintenance requirements, and are suitable for continuous operation.

DC Motors

DC motors, or direct current motors, operate on direct current and provide precise speed and torque control. They are commonly used in applications that require adjustable speeds or when a high starting torque is needed. DC motors find applications in robotics, automotive systems, and battery-powered devices.

Brushed Motors

Brushed motors consist of a rotor with windings and a commutator (a device that provides electrical connections to the windings). The commutator enables the flow of current in the windings, creating a magnetic field that interacts with the stator's magnetic field. Brushed motors are simple in design, inexpensive, and suitable for low-power applications. However, they require regular maintenance due to the wear of the brushes.

Brushless Motors

Brushless motors, as the name suggests, do not have brushes or commutators. Instead, they use electronic controllers to switch the current in the windings, allowing for precise control and high efficiency. Brushless motors are commonly found in appliances, power tools, and electric vehicles.

Stepper Motors

Stepper motors are special types of motors that move in discrete steps, making them suitable for applications that require precise position control. They find applications in CNC machines, robotics, and 3D printers.

Working Principles of Electric Motors

Electric motors operate based on the principles of electromagnetic induction and the conversion of electrical energy to mechanical energy. The working principles can be summarized as follows:

Magnetic Field Generation

Electric motors generate a magnetic field using a combination of permanent magnets and coils of wire carrying an electric current. The interaction between the magnetic fields of the rotor and the stator leads to the generation of mechanical motion.

Electromagnetic Induction

When an electric current flows through a wire, a magnetic field is created around it. Similarly, when a wire passes through a magnetic field, an electric current is induced in the wire. Electric motors utilize this principle of electromagnetic induction to convert electrical energy into mechanical energy.

Conversion of Electrical Energy to Mechanical Energy

Electric motors convert electrical energy into mechanical energy through the interaction between magnetic fields. When an electric current flows through the wire windings in the rotor, the resulting magnetic field interacts with the stator's magnetic field. This interaction creates a force that drives the rotational motion of the rotor.

Advancements in Electric Motor Technology

Advancements in electric motor technology have brought about significant improvements in efficiency, performance, and reliability. Some key advancements include the development of high-efficiency motors, variable speed drives, and rare earth magnet motors.

High-Efficiency Motors

High-efficiency motors, also known as premium efficiency motors, provide increased energy efficiency compared to standard motors. They incorporate design enhancements such as improved insulation, reduced losses, and optimized motor cooling. High-efficiency motors help reduce energy consumption, lower operating costs, and contribute to sustainability initiatives.

Variable Speed Drives

Variable speed drives (VSDs) allow for the control of motor speed and torque, providing flexibility and energy savings in various applications. By adjusting the motor's speed to match the load requirements, VSDs optimize energy consumption and reduce wear and tear. VSDs are particularly beneficial in applications with varying load demands, such as HVAC systems and pumping systems.

Rare Earth Magnet Motors

Rare earth magnet motors utilize powerful magnets made from rare earth elements such as neodymium and samarium cobalt. These magnets offer higher magnetic strength compared to traditional magnets, resulting in motors with higher power density and improved efficiency. Rare earth magnet motors are commonly used in hybrid and electric vehicles, wind turbines, and other high-performance applications.

Applications of Electric Motors

Electric motors find application in a wide range of industries, providing power and motion for various systems. Some notable applications include:

Automotive Industry

Electric motors are at the heart of electric and hybrid vehicles, providing propulsion and powering auxiliary systems such as power steering and air conditioning. Electric vehicles (EVs) are gaining popularity due to their lower emissions, improved efficiency, and advancements in battery technology.

Industrial Manufacturing

Industrial manufacturing relies heavily on electric motors to power machinery, control systems, and automation. Electric motors drive pumps, compressors, conveyors, and robotics, enabling efficient and precise operations in industries such as automotive, pharmaceuticals, and food processing.

Renewable Energy Systems

Electric motors play a crucial role in renewable energy systems, supporting the generation of clean and sustainable power. Wind turbines use electric motors to convert the rotational energy of the blades into electrical energy. Solar panel tracking systems also utilize electric motors to adjust the position of the panels for maximum sun exposure.

Consumer Electronics

From household appliances to power tools and entertainment systems, electric motors are present in various consumer electronics products. Electric motors power refrigerators, washing machines, vacuum cleaners, and handheld devices, providing the necessary mechanical motion for their functions.

Case Studies: Real-World Applications

Tesla's Electric Vehicle Powertrain

Tesla, a leading manufacturer of electric vehicles, has been instrumental in driving innovation in electric motor technology. Their electric vehicle powertrain utilizes advanced electric motors, which deliver high performance and efficiency. Tesla's Model S, for example, utilizes a three-phase, four-pole electric motor that generates torque without the need for a traditional gearbox. This design allows for smooth acceleration, regenerative braking, and efficient energy usage.

Wind Turbine Generators

Electric motors play a vital role in wind turbine generators, converting the rotational energy of the blades into electrical energy. The generator rotor is driven by a low-speed shaft, which is connected to the blades. As the blades rotate, the rotor spins within a magnetic field, generating an electric current. Electric motors are also used in wind turbines for blade pitching, yaw adjustment, and nacelle control.

Robotic Automation in Manufacturing

Robotic automation is on the rise in manufacturing industries, with electric motors serving as the driving force behind these automated systems. Electric motors power robotic arms, conveyor systems, and assembly line equipment, enabling high-speed, accurate, and repetitive tasks. Industrial robots utilize electric motors with precise control capabilities, ensuring optimal performance and productivity.

Efficiency and Environmental Benefits of Electric Motors

Electric motors offer several efficiency and environmental benefits compared to traditional combustion engines or other forms of mechanical power. Some key benefits include:

Reduced Carbon Footprint

Electric motors produce zero direct emissions during operation, resulting in a significantly reduced carbon footprint compared to internal combustion engines. By transitioning to electric motor-powered systems, industries and transportation sectors can contribute to global efforts to mitigate climate change.

Energy Saving Potential

Electric motors are highly efficient, with some modern motors achieving energy conversion efficiencies above 95%. The use of high-efficiency motors and variable speed drives can further optimize energy consumption by matching motor speed to the load requirements. Improved energy efficiency reduces energy waste and leads to cost savings.

Lower Maintenance Needs

Electric motors require less maintenance compared to internal combustion engines. With fewer moving parts and no fuel or oil changes, maintenance costs are significantly reduced. Electric motors also offer longer lifespans, reducing the need for frequent replacements.

Challenges and Future Trends in Electric Motors

While electric motors offer numerous benefits, there are still challenges and future trends to consider. Some key challenges include the integration of battery technology with electric motors, the electrification of transportation, and industry shifts towards sustainable energy solutions.

Battery Technology and Electric Motor Integration

As electric vehicles become more prevalent, the development of advanced battery technologies becomes crucial. High-performance batteries with improved energy density and faster charging capabilities will drive the adoption of electric vehicles and support the integration of electric motors in various applications.

Electrification of Transportation

The electrification of transportation goes beyond electric vehicles. Other forms of transportation, such as trains, ships, and airplanes, can also benefit from electric motor technology. Advancements in electric motor technology and infrastructure will pave the way for more sustainable and efficient transportation alternatives.

Industry Shifts towards Sustainable Energy Solutions

As the world moves towards a more sustainable future, industries are increasingly adopting electric motor-powered systems. The shift towards renewable energy sources such as wind and solar power further drives the demand for electric motors. This transition requires investments in research, development, and infrastructure to facilitate the widespread adoption of electric motor technology.

Expert Insights and Quotes

Dr. Paul Oh, Distinguished Professor of Robotics, Purdue University: "Electric motors are the heart of many modern-day machines and systems, playing a critical role in driving innovation and improving sustainability."

Chris Onder, Chief Engineer at General Motors: "Advancements in electric motor technology have allowed us to push the boundaries of efficiency and performance in our electric vehicles, providing an exciting driving experience while reducing emissions."

Conclusion

Electric motors are indispensable in our modern world, powering innovation and driving sustainability across various industries. This article has provided an extensive overview of electric motors, their types, working principles, and advancements in technology. Real-world applications and case studies have highlighted the diverse applications of electric motors in sectors such as automotive, industrial manufacturing, and renewable energy. The efficiency and environmental benefits of electric motors have been emphasized, along with the challenges and future trends in the industry. As electric motor technology continues to evolve, it is crucial for professionals and researchers to engage in further research and professional dialogue to explore its full potential in shaping a sustainable future.

References

Topics